How To Make A Sextant Model

| level of difficulty | beginner | intermediate | avant-garde |

The CD-Sextant

Build your own sextant

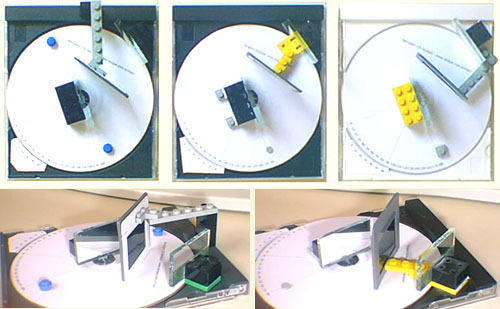

A few months ago I published the Ten-tant Project , a "practise-it-yourself" sextant design. But the instrument construction requires some skill, electric tools, some hard to observe materials and considerable work. Then I went on to design an even simpler sextant, which is called CD-Sextant. This small-scale instrument is built with an old CD and its instance. Every bit in the X-Tant Projection, I used a few Lego blocks and glass mirrors. No electric tools are necessary to build a CD-Sextant.

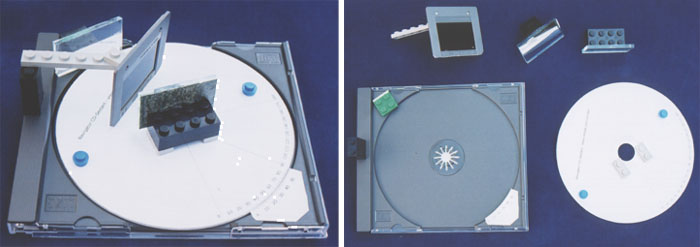

The CD-Sextant (assembled and parts)

The needed materials are:

| |

|

The design takes advantage of the dimensional precision of CD parts and Lego bricks. The sextant arm is the CD itself and the sextant frame is the CD box. The angle is inverse by turning the CD.

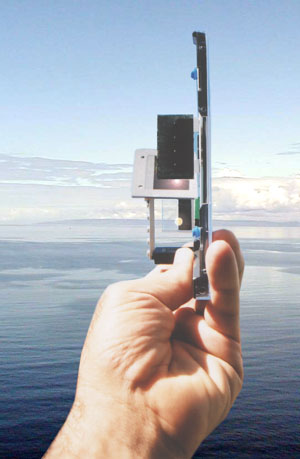

Of class the modest CD radius gives limited precision to the instrument when compared to larger sextants, only it is enough for angelic navigation exercise. Because the instrument is then small, care must be taken in all steps (cutting, sticking etc) to accomplish the best possible precision.

The CD-Sextant is non only useful for celestial navigation, but also in coast navigation, using simple trigonometric relations. And information technology is surprisingly strong (I have dropped mine a couple times, with pieces flying in all directions, and it is even so working).

Vernier scale sextants

Minutes of arc are very small and reading them is only possible with a precise calibration. There are ii kinds of infinitesimal scales used in sextants. Modern sextants utilise a drum to trim the musical instrument and read the minutes. I total turn of this drum equals one degree ( or 60' ). This device requires sophisticated machining to build.

The CD-Sextant uses a vernier scale, a simpler merely useful minute scale type. Since the CD-Sextant degrees are small ( due to the small CD radius ) I used a single threescore' vernier (larger sextants usually divide each degree in iii ticks of twenty' ).

For more details on vernier scales click here.

Press the Scale

The scale is the nearly hard sextant component to do using traditional techniques. Fortunately, most of united states of america have a precise printing equipment right on our desktop: an ink jet or laser printer. These machines tin can print 300 dots per inch (1200 for laser), with plenty precision to print a sextant scale.

Sextant scale printer program

In order to achieve the best results, I wrote a small sextant scale printing program. This volition print the sextant scale using vector rendering, for all-time resolution. This is the same program used in the X-tant project.

XtantScalePrinter - version 1.1 - download here ![]()

For Windows, 192.874 bytes - This programme can exist freely used for personal, noncommercial purposes, provided that the credit (name and URL) is not removed from the printed scales.

1) To print the CD-Sextant scale, run the plan and cheque the CD-Sextant checkbox.

two) The CD-Sextant is a vernier sextant (see 10-tant Project for more details on Verniers). In the instance of the CD-Sextant, the small-scale scale radius makes it incommunicable to split up the scale degrees into smaller ticks. Set the div/degree property to 1. This will give a scale with ticks merely for full degrees and a sixty' vernier.

3) Select your favorite font. Apply size 7.

iv) Press the [Print scale] push button.

5) After printing, cut around the scale precisely. Don't cut the CD axis hole nevertheless.

Sticking the scale

Sticking the scale is a critical functioning. If the calibration is not perfectly centered when y'all stick, you will probably take to remove it in pieces and print a new one. I did this:

| 1) Lift an edge of the sticker paper backing, in the scale part. | |

| 2) Cut the newspaper bankroll edge, to expose a modest expanse of the sticker surface. |

| 3) Position the calibration on the CD (use the data side), making sure the calibration is perfectly centered. Await confronting a light source to check if calibration is centered in the CD heart hole. Hold the CD and printed scale with both hands, making sure the printed scale is non out of the CD in whatever side. |

| 4) One time the scale is centered, printing the exposed sticker surface against the CD to stick it. This will secure the scale to the CD in the correct position. | |

| 5) Remove the rest of the sticker paper backing and carefully stick the scale, working in one direction, to avoid bubbles and ripples. In the end, the printed calibration must be centered and match CD surface perfectly. 6) Use the paper cutter to open up the CD axis hole. |

Relieve the printed Vernier (the small scale). Information technology volition be the final thing to be stuck, later on the mirrors are positioned.

Mirrors

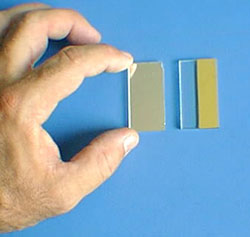

I used ii equally sized glass mirrors (40 mm 10 22 mm, iii mm tick). Any glass shop will cut these for you lot. As yous know, ane of the mirrors must exist half silvered. So you must remove half of the mirror silver backing. I used a paper cutter blade for this job (Olfa cutter).

| First make a sharp longitudinal cut along the centre of the mirror. And then scratch half of the epoxy protective layer from the back of the mirror, scratching with the cutter blade inclined. The epoxy backing is a difficult material, but will come up out with patience. Go easy and don't use any annoying material or the bract point, to avoid scratching the glass. Once the epoxy is gone, the silver is easy to remove, rubbing with a wet cloth or thin steel sponge (the ones used to clean windows). In the end, the glass must be articulate and scratch free (fig. below). |

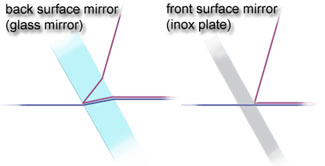

| Note: You may exist tempted at this point to apply a thinner mirror and eliminate the transparent role altogether. Don´t do that. This would introduce a refraction error. The direct (horizon) light ray must pass thru the glass, every bit the low-cal ray from the star does. This can merely be done if you use a forepart mirrored surface, such as a polished inox plate. However inox mirrors are hands scratched. Glass mirrors are better. |  |

Mirror supports

I used Lego bricks to concord the mirrors. They have good dimensional precision and will guarantee a near correct xc° angle betwixt the mirrors and CD parts. They will likewise let the sextant to be assembled, disassembled, trimmed and parts to be replaced as needed.

Of course other materials can be used if Lego bricks are non available. Attempt to utilise dimensionally precise objects, to build the mirror supports with right angles.

Bonding the mirrors

CD Eye mirror:

| 1) Working on a flat surface, bail the center mirror dorsum to the large side of a 2x4 Lego brick. Make sure the mirror is perpendicular to the flat surface. |

| two) Gather the 2x4 brick over ii 2x1 Lego plates (gray ones). The space between the plates volition be over the CD centrality hole. 3) Bond the mirror assembly to the CD. A few things to watch hither:

|

CD Box mirror (half silvered):

| > high definition 300 DPI image | I used a 2x2 Lego brick mounted on a 2x2 Lego plate, to concord the CD box mirror. Cut the iv brick bumps out, considering they will exist visible thru the transparent part of the half silvered mirror. 1) Working on a flat surface, bail the one-half silvered mirror to the 2x2 Lego brick. Make sure the mirror is perpendicular to the flat surface. 2) Assemble the box mirror brick to the plate. three) Position and bond the box mirror assembly in the CD box corner. Make sure that:

|

Sticking the Vernier

At this betoken, your CD-Sextant is near done. You must now stick the Vernier in 0° position:

1) Cut the vernier in a triangular form, to fit the CD box corner. I did stick the vernier on a bare sticker paper piece, in society to make the vernier paper ticker. This is of import because the vernier edge will be unsupported.

1) Trim the mirrors (run into trimming the mirrors beneath)

2) Plow the CD until the mirrors are parallel.

3) Concord the instrument in ascertainment position, looking thru the one-half silvered mirror and focus on a far abroad object. Turn the CD slowly until the reflected image and the directly image coincide. This must exist the instrument zero, then....

4) ...Carefully place and stick the vernier in the CD box, reading 0°00'. This ways that the vernier tick A most coincide with the 0° calibration line. On the other side of the vernier, the 60' tick must coincide with the 59° tick in the scale.

Make sure the vernier and CD calibration are very close together. The vernier probably will be a little higher than the CD, and you might desire to bend it downwards a fleck.

Shades

![]() Observing the Sunday can be unsafe. The UV radiations can cause cataracts. Excessive visible light tin can burn the retina. Extreme care must be taken while observing the Sun, to protect your eye. This means your musical instrument must have a good Sunday filter.

Observing the Sunday can be unsafe. The UV radiations can cause cataracts. Excessive visible light tin can burn the retina. Extreme care must be taken while observing the Sun, to protect your eye. This means your musical instrument must have a good Sunday filter.

Tips:

- Make sure the shade is in place before observing the Sun.

- Avoid observing the Sunday for more a few seconds.

- Never stare the Sun directly.

- If you lot experience uncomfortable, stop the ascertainment immediately.

- In this case, consider a stronger filter.

Materials that can be used to make the filter:

- Aluminized Mylar film - this is a material specifically developed for solar observation. Can be constitute in science supply stores. Probably the best material available.

- Welder's glass - strong filter, used to protect the welder eye. Difficult to cut, can be constitute in construction stores.

- Photography film. Use a dark negative with silvery coating. This means black-and-white moving picture. Colour motion picture does not comprise silver and will not filter the UV rays (they are dark for visible calorie-free, but not for UV light).

- Night floppy disk media.

For more than on heart condom, read this page .

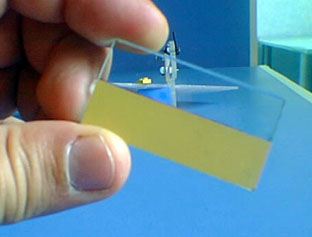

As shades for Sun and Moon sights, I used 35 mm night negative film (there is 1 in the finish of every film gyre). The negatives were mounted in slide frames. I used two layers of dark movie for the Dominicus frame and single for the Moon. Both slide frames are removable and are attached to the musical instrument frame using Lego pieces. I did trim the lower border of the slide, to brand it thinner. The slide window must match the imaginary "tube" formed by the mirror edges.

Edit: 2019 - Well-nigh nobody uses this kind of photographic film anymore, so I recommend using dark "welder helmet" shades ( as in construction shop for shade number #xiv )

| In the image to the left we have 3 dissimilar shade back up designs. The shade must be positioned betwixt the two mirrors and the filter surface must exist orthogonal to the line connecting both mirror centers. This is to avoid introducing a refraction fault. Attempt to position the slide centre in the line connecting the two mirror centers. The Sun observation is made by looking thru the one-half silvered mirror, below the shade. |

Trimming the mirrors

| For simplicity, the CD-Sextant is non equipped with screws to trim the mirrors. But the mirrors can be trimmed by inserting small sticker newspaper pieces betwixt the Lego brick and plates (or past sanding the brick) at suitable positions. First check the angle of the CD mirror (center mirror). Equally you look to this mirror, the reflected CD edge must be perfectly aligned with the edge you see outside the mirror (dark-green arrows in the image). This must concur for all directions. The one-half silvered mirror can be trimmed past setting the musical instrument to 0°00', aiming to a far abroad object and making sure the direct and reflected images coincide. After this initial trimming, the Lego bricks volition hold the trimming surprisingly, even after disassembled. Of grade you must read the alphabetize mistake after each gear up of observations, equally with all sextants. | |

| | Final touches Bond a circular 1x1 Lego piece to the CD surface, to use as a turning knob (the blue slice). The CD may be hard to turn. In this case, rub the CD hole with a pencil. The graphite is a expert lubricant, and volition brand turning the CD easier. This is of import for fine adjustments. I made viii such sextants. -10-x-x-x-10- |

Bibliography

| >> "The American Practical Navigator " by Nathaniel Bowditch ISBN 0781220211 - 1200 pages | ||

Source: https://www.tecepe.com.br/nav/cdsextantproject.htm

0 Response to "How To Make A Sextant Model"

Post a Comment